ISEA SBR Equalized System: advanced wastewater treatment

ISEA's Equalized Sequential Batch Reactor (SBR) system is an advanced wastewater treatment solution designed to provide high levels of treatment by alternating aerobic and anaerobic stages. This innovative, automated system offers key advantages over traditional activated sludge systems.

SBR in detail

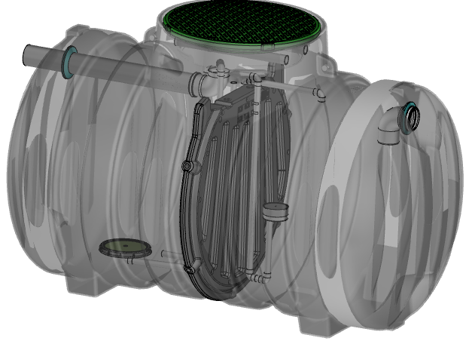

Secondary treatment (biological reactor)

This is where the biological processes take place; by adding O2 to wastewater containing organic matter, biomass (activated sludge) is generated, which metabolizes the organic matter, transforming it into easily settleable substances, thus separating it from the already treated water.

Competitive Advantages

Maximizing efficiency

High performance complete solution

Handles variable organic loads and adapts to different wastewater volumes.

High quality material (PE)

Durable and recyclable material.

Programmable and energy-efficient system

Fully automated and integrated sludge system with a programmable control unit based on the presence of inhabitants. The system minimizes energy consumption thanks to the air blower and programmable system.

Safety and reliability

The system has been tested for 9 months by an independent laboratory (PIA) and meets strict local and European environmental standards. PIA certification guarantees high effluent quality compatible with effluent discharge.

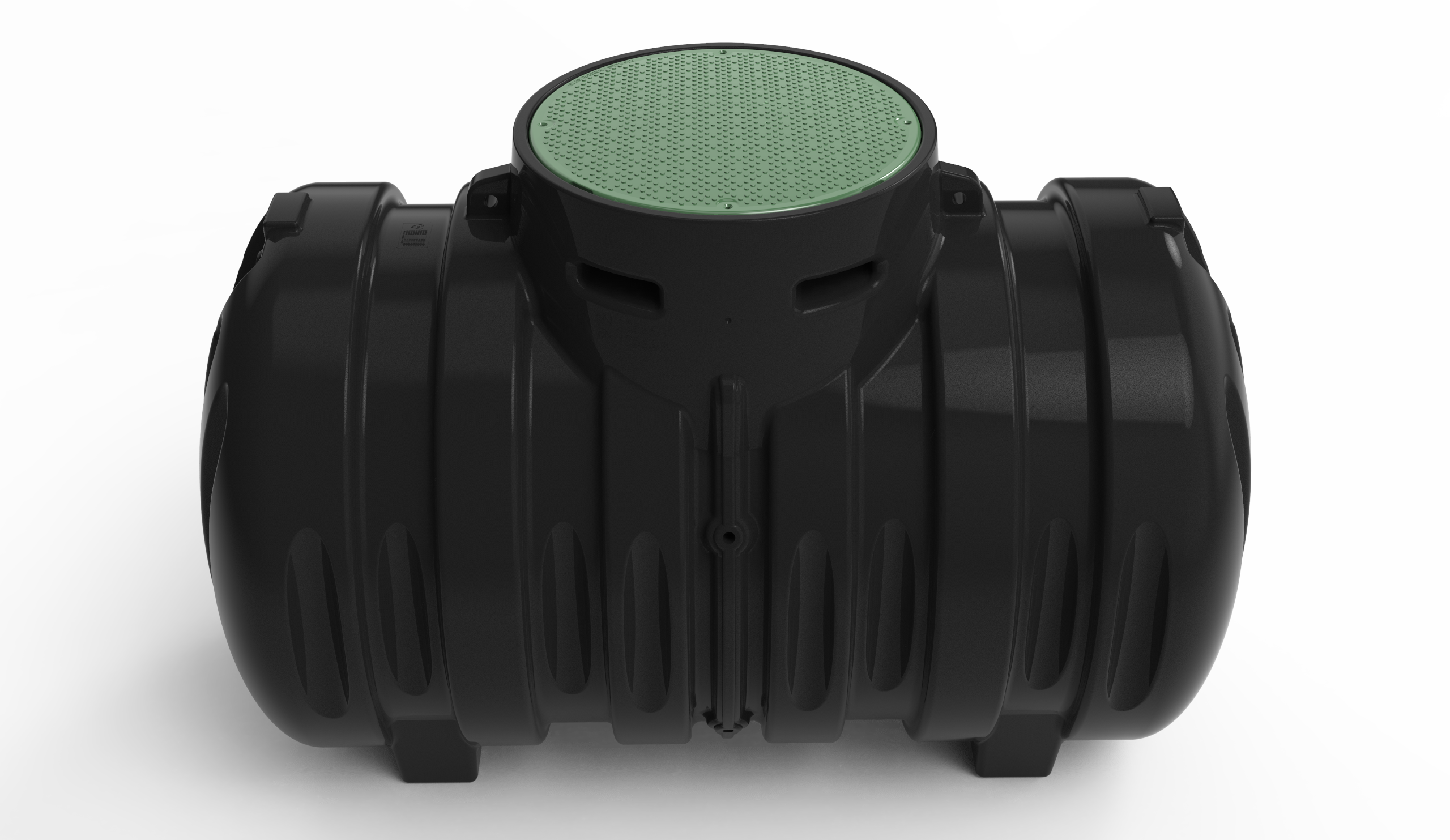

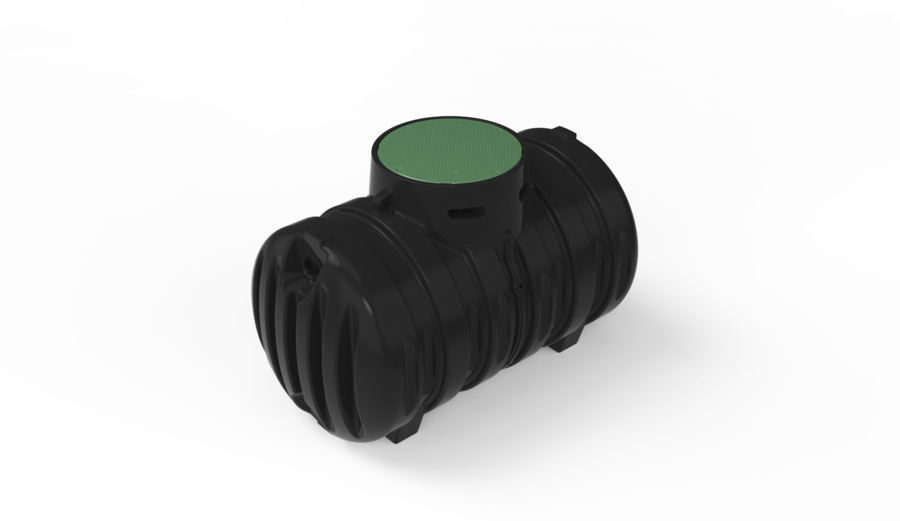

Compact and accessible design

Designed to save space, with easy access for maintenance.

Compactness of the tank, including covers and extensions (large, accessible with watertightness).

Ready to install

Ready to connect, the SBR equalized system is pre-assembled, ready to connect, reducing on-site installation time.

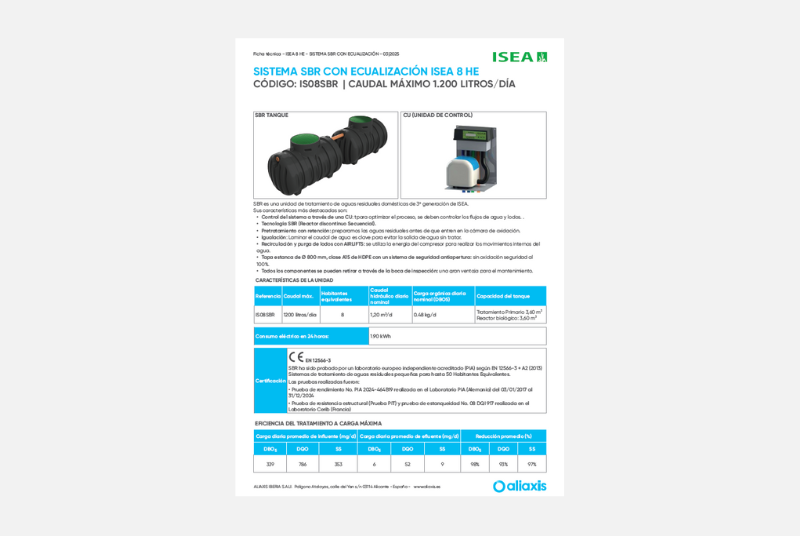

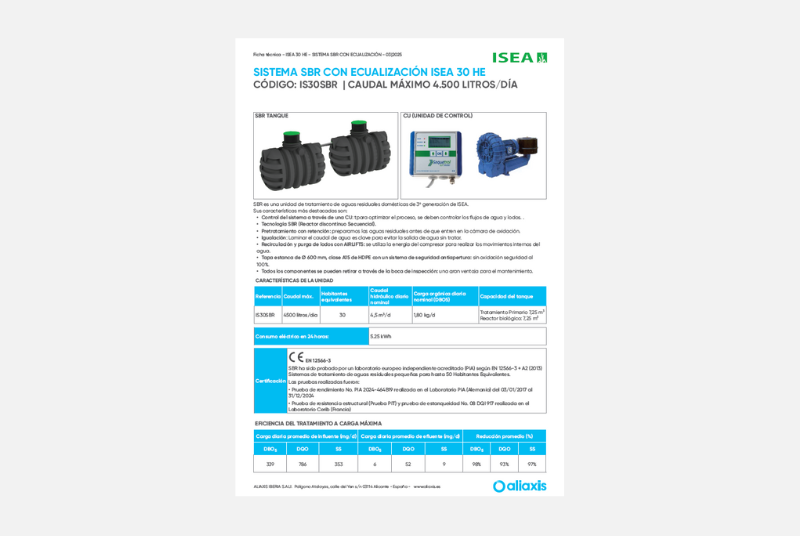

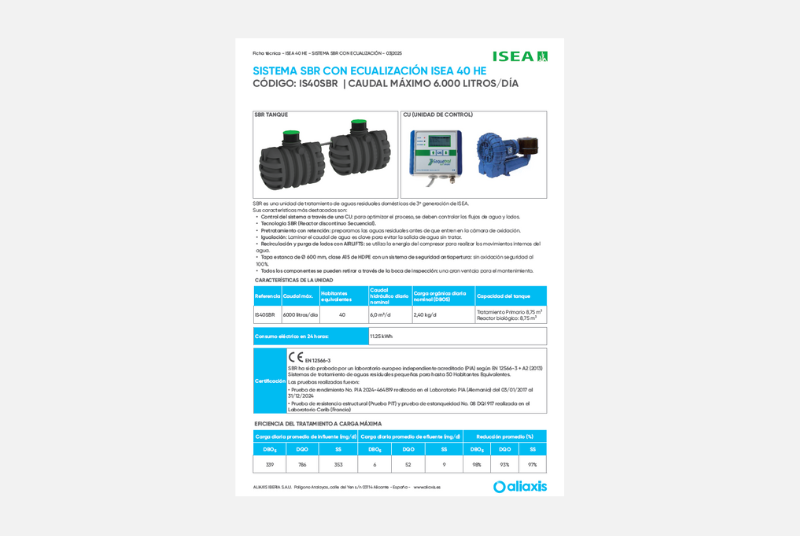

Technical Specifications

Key technical elements

Tank or reservoir

- Horizontal tank for underground installation: robust and low height.

- Enclosure included: cost savings in installation.

- Watertight HDPE cover: safety and aeration control.

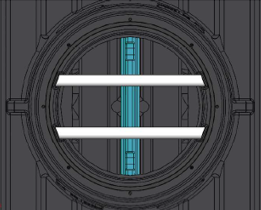

Additional features

- HDPE cover class A15.

- Anti-drop bars. Nominal opening Ø600 mm: the bars offer security against carelessness.

Control Unit (CU)

Manages scheduling, allows program changes.

How the ISEA SBR system works

Sequenced Batch Reactor (SBR) technology is an advanced method of wastewater treatment using a fill-and-extract activated sludge system. It is highly effective for the treatment of domestic and industrial wastewater.

Unlike continuous systems or other SBR versions, in this evolution we combine settling and equalization with the sequential reactor to fully control the flow and performance of the system.

Sedimentation and equalization

2. Filling of the reactor

3. Aerobic phase

4. Anoxic sedimentation

5. Sludge recirculation

6. Clean water outlet

Ideal Applications

The SBR equalized system is ideal for a variety of applications, including:

Domestic wastewater treatment:

Ideal for homes and small communities.

Industrial wastewater treatment:

Handles high organic loads and industry-specific pollutants.

Our commitment to sustainability

A resilient solution to today's and tomorrow's water challenges

Energy efficiency: Designed to minimize energy consumption.

Resource conservation: Effectively treats wastewater, allowing safe discharge of effluent and reducing water waste.

Environmentally friendly materials: Constructed of PE, known to stand the test of time and be a recyclable material, to ensure minimal environmental impact.

get_app

get_app